content is empty!

| Availability: | |

|---|---|

| Quantity: | |

Product Description

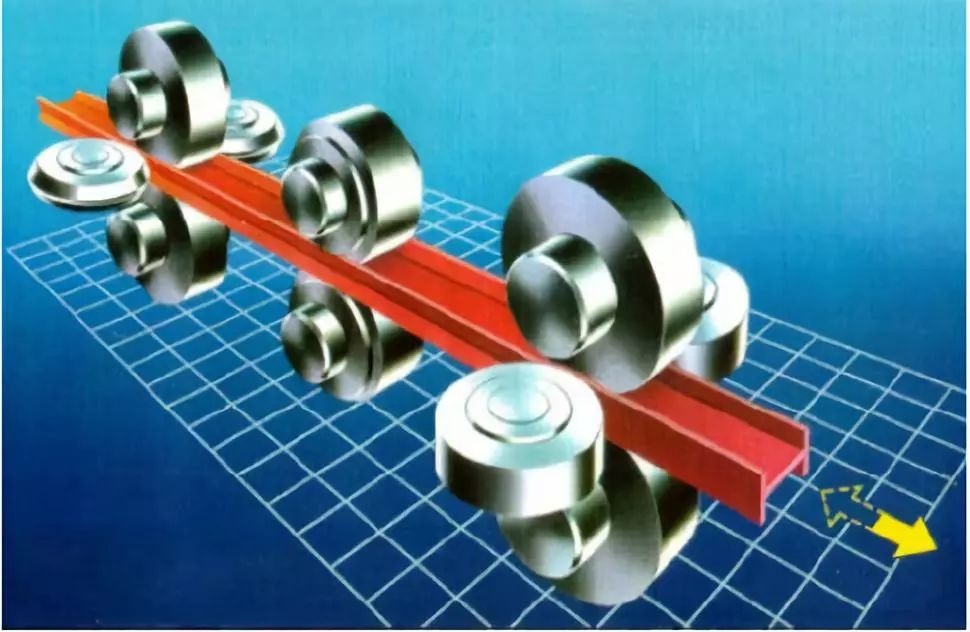

Metal processing: The core function of the universal rolling mill is to roll metal raw materials. Pressure is applied to the metal through the roll, causing it to pass through the roll gap, thereby changing the shape and thickness of the metal. This processing method is suitable for various metal materials, such as steel, aluminum and so on.

Improve material properties: In addition to the basic rolling function, the universal mill can also improve the physical properties of metal materials through specific processing technology and parameter adjustment. For example, it can improve the toughness, hardness, wear resistance of the metal, etc., to provide high-quality raw materials for the subsequent manufacturing process.

Adapt to a variety of production needs: the design of the universal rolling mill is flexible and can adapt to different production needs. Different specifications and requirements of metal materials can be produced by adjusting the parameters of roll spacing, Angle and rolling speed. This makes the universal rolling mill has a wide application prospect in the field of metal processing.

Improve production efficiency: Compared with traditional metal processing methods, universal rolling mill has high production efficiency and good processing quality. It can realize continuous and automatic rolling production, greatly improve the processing efficiency of metal materials, and reduce the production cost.